The word Metalock stands for a highly successful technology intended for the repair of cracked or broken cast iron or cast steel. This cold process originated in the oil fields of Texas in the 1930’s; it was developed to eliminate the dangers of open flame welding in inflammable conditions.

The process had many ancillary advantages, such as the absence of heat meaning the elimination of distortion, reduction in post repair machining and pressure tightness.

Metalock (Britain) Ltd was created in 1947 and its great success led to the creation of the Metalock International Association in 1953. The original members were the companies from UK, France, Sweden and Norway. These partners funded associated companies throughout the world. Most, not all, used the Metalock name. Today these and further independent companies are members of the Metalock International Association.

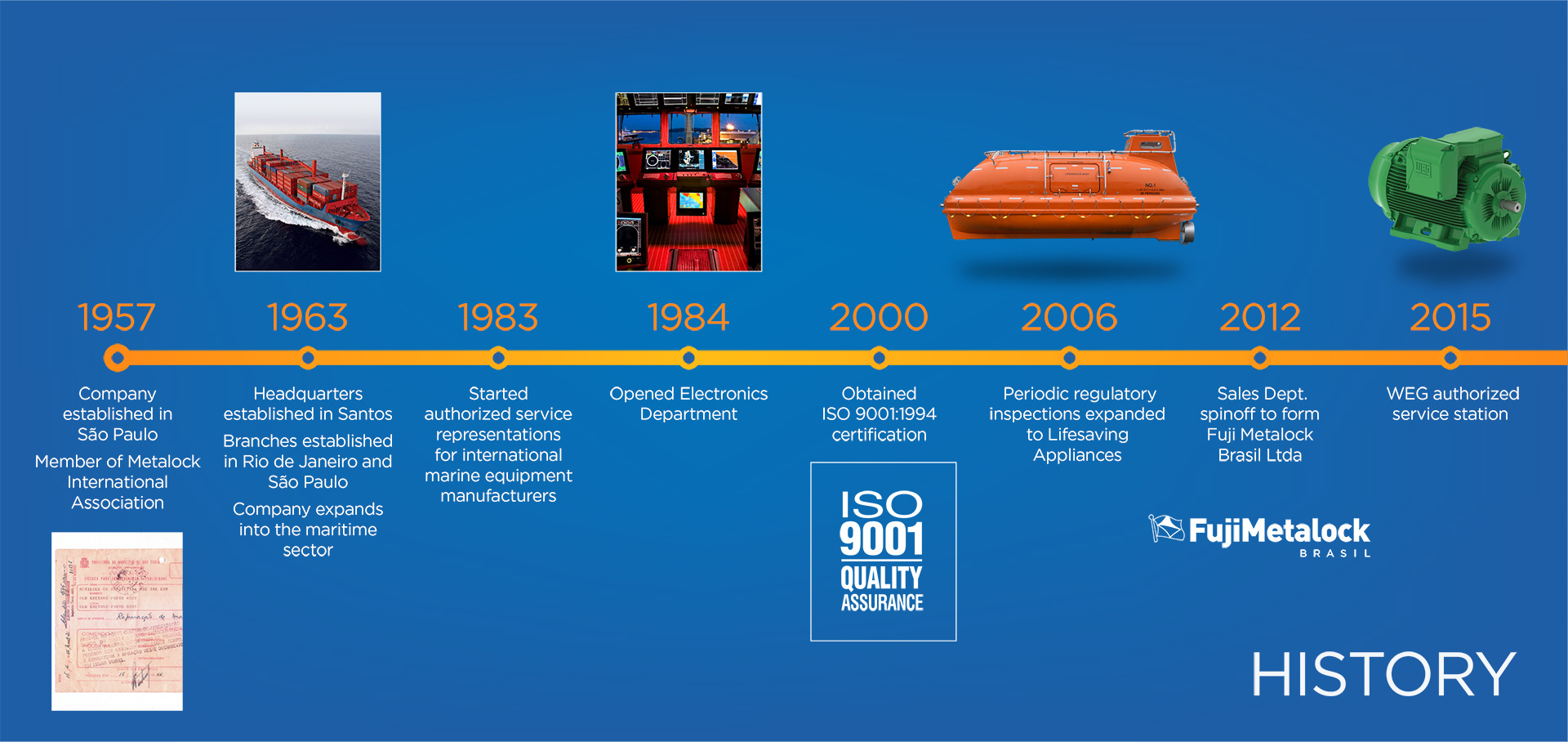

Metalock activities in Brazil started in São Paulo, in June of 1957, with the name Unilock. The basic activity then was performing repairs to cold cast iron components, mainly for industrial and marine equipment, such as diesel engines. At that time, most industrial machinery was made in cast iron and the repair market expanded because there was a shortage of spare parts, as a consequence of the war. During those initial years, there was considerable demand for marine equipment repairs in Brazil. When steel substituted cast iron in equipment, Unilock, who was by then well established in the industrial market, diversified its activities. In January of 1961, it took over Oficina Duncan, a marine engineering service company in Santos, and after this acquisition the new company adopted the name Metalock Brasil Ltda., adding marine engineering services market to its activities.

The company expanded considerably its engineering services in the industrial, marine and offshore markets in Brazil, building itself a reputation for reliable services conducted in-house – cold stitching (Metalock®), mechanical, machining, in-situ machining, welding, plate work, boiler work, electrical, electronics, pneumatics, hydraulics, propulsion, refrigeration, electroplating, safety inspections.

Metalock Brasil are official service representatives for many manufacturers of marine equipment and its technicians regularly attend training courses at these manufacturers abroad, keeping abreast of technological developments and methods. In addition it has close working arrangements with other marine equipment manufacturers. Its repair teams are accustomed to working abroad, on board vessels during voyages and are readily deployed to anywhere in the world.

Metalock Brasil provides a One Stop Shop concept, offering customers the convenience of centralizing all repair and inspection technical services in a single supplier, operating 24/7, greatly reducing costs and operational downtime.

Metalock Brasil is ISO 9001:2015 certified by DNV.