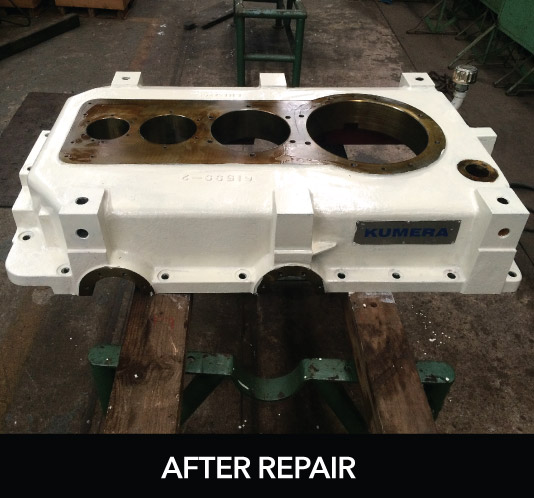

Metalock® Repair is the high-tech, cold repair to iron and steel castings that are cracked and/or broken.

This procedure originated in the 1930s in the Texan oil fields with the objective of avoiding the fire hazard of using welding techniques.

The Metalock® repair involves a critical analysis of the damaged material to identify the cause of the damage.

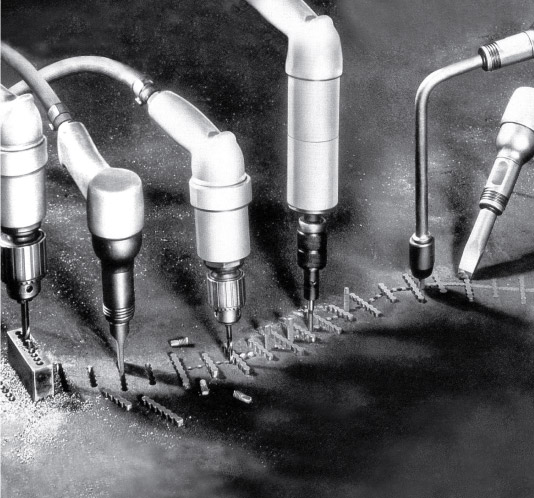

1 – Draft and establish measurements of the repair.

2 – Open apertures for the reinforcements.

3 – Adjust the reinforcements in the apertures.

4 – Fasten the reinforcements.

5 – Peen the reinforcements.

6 – Necessary finishing (Machining, grinding, painting)

Advantages of the process :

1 – No introduction of new stresses in the base material.

2 – Restores mechanical ridgidity to the equipment.

3 – Can be done on site, reducing down time.

4 – Maintains surface alignment.