A company in the Cellulose Pulp and Paper industry suffered damage in the main shaft bearing of CD2 filter and contacted Metalock Brasil for its repair.

After analyzing the initial condition of the shaft, Metalock Brasil’s specialized technicians found the shaft extremity of the CD2 filter with major damage due to bearing failure. Metalock Brasil’s engineering team devised and projected a repair method, using in-situ machining.

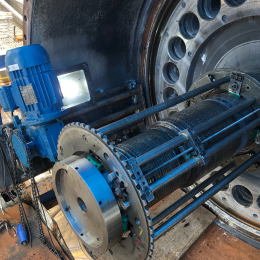

Metalock Brasil’s welding and platework team fabricated and fitted a device used to support the reduction gear assembly. The in-situ machine, prepared and adapted for the job, as then assembled and aligned, using as reference the best points in the region of the bearing and that of the mechanical seal.

After the equipment was centered the machining process began. The machine was designed in order to be able to simultaneously machine the outer diameter of the region of the mechanical seal and that of the bearing, thus increasing service productivity. The machined regions were left with an excess of metal, making it possible to finish off with the polishing process.

Separate specialist equipment for this was assembled and the regions of the mechanical seal and bearing were polished to their final measurements of 247mm f7 and 216mm f7 respectively, with all surface finishes within the acceptable tolerance.

The work was completed to the satisfaction of the client’s Technical Department and the repaired CD2 filter was left in perfect working order.

Voltar